Drone Cleaning System DJI Flycart 30

The Drone Cleaning System is an advanced aerial cleaning system designed to be integrated with heavy drones. With multi-angle spraying, 30L tank and remote control, it provides effective maintenance of wind turbines, solar panels, towers and hard-to-reach surfaces, improving safety and operational efficiency.

From 11.590,00 € VAT incl.

Limited stock – Shipped in 24-48 h

Drone Cleaning System DJI Flycart 30

Drone Cleaning System DJI Flycart 30

The Drone Cleaning System is an innovative high-pressure cleaning system designed to be mounted on heavy drones, enabling automated and efficient cleaning operations on hard-to-reach surfaces. With its multi-angle spraying capability and integration with large drones such as the DJI FC30, it is a state-of-the-art solution for maintaining critical infrastructure, including wind turbines, solar panels, insulators, buildings, and transmission towers.

Designed to improve efficiency and safety in high-altitude operations, the Drone Cleaning System eliminates the need for risky manual intervention by allowing operators to perform cleaning remotely and automatically. Its foldable modular design, high-capacity 30-liter tank, and adjustable nozzle make it a versatile and easy-to-carry tool perfect for large-scale industrial applications.

Main Features

- Compatible with heavy drones: Integrated with industrial drones such as the DJI FC30 for unified control.

- Multi-angle cleaning: Adjustable nozzle with automated spraying and path planning.

- Foldable design: Folding arm up to 1 meter for easy transport and storage.

- 30L tank: High capacity for continuous operations and reduced refills.

- Adjustable nozzle: Spray angles from -60° to +35° vertically and ±45° horizontally.

Main Benefits

- Increased efficiency: Automated spraying and 30L tank to reduce downtime.

- Maximum safety: Remote control that eliminates the risks of high-altitude operations.

- Versatility: Suitable for wind turbines, solar panels, transmission towers and buildings.

- Easy operation: Unified control with the drone for simplified operations.

- Reduced operating costs: Minimizes the need for expensive personnel and equipment.

- Optimized cleaning: Adjustable nozzle to suit different surfaces and dirt levels.

Efficient – Adjustable nozzle angles, path planning, full process automation

Rapid Suspension Cleaning

Adjustable nozzle angles (-60° to +35° vertically, ±45° horizontally) for fast, efficient, large-scale cleaning.

Planning the Spraying Route

Allows pre-planned spraying with optimized direction and angle, enabling automatic spraying along the programmed path.

Complete Process Automation

It combines spray route planning with flight planning, resulting in a fully automated operation.

Efficient – Large capacity, easy to learn, easy to carry

30L Large Capacity Tank

Covers large areas in a single operation, reducing the frequency of tank changes.

Enables quick refills of liquids, improving continuous operating efficiency.

Foldable and Easy to Transport

The spray module can be folded up to 1 meter, making it easy to store and transport.

Suitable for different types of vehicles for convenient transportation.

Seamless Integration with Flight Control

Fully integrates with flight systems, enabling one-man control of both drone and sprayer.

Safety – Unmanned safety operations at high altitude

Drone Cleaning System DJI Flycart 30

Challenges of Traditional Cleaning at High Altitude.

Safety Risks: Working at high altitudes involves significant risks, exacerbated by weather changes and strong winds in complex environments.

Health Risks: Working at great heights for long periods can have adverse effects on the physical health of operators.

Remote Operation with Drone Cleaning

✔ Eliminates safety hazards: Reduces risk by allowing operators to control the system remotely, directly from the ground.

✔ Increased safety: The Drone Cleaning System ensures that operations remain within safe limits, improving overall safety in complex, high-altitude environments.

Safety – Real-time distance detection and effective working radius of 6m

Real-Time Laser DistanceSensing

The sensing module displays the operating distance in real time, ensuring stable and optimal spraying.

Radius of 6mEffective

Enables effective operations within a radius of 6 meters, providing wide operational coverage and ensuring safety.

Versatility – Adaptable and highly flexible nozzles

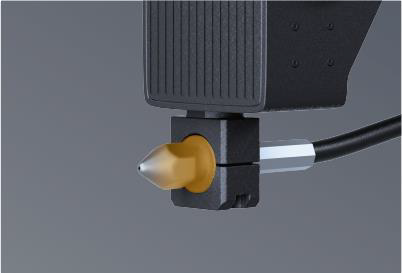

Modular Nozzles

They adapt to different tasks with the most suitable nozzle, enhancing equipment versatility in various operating scenarios.

Multi-angle spraying

Enables effective coverage of surfaces in tight spaces with multi-angle adjustment, making it ideal for different cleaning scenarios.

Application Scenarios

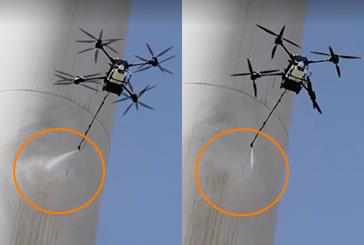

Cleaning of Wind Turbines

Cleaning of Electrical Networks

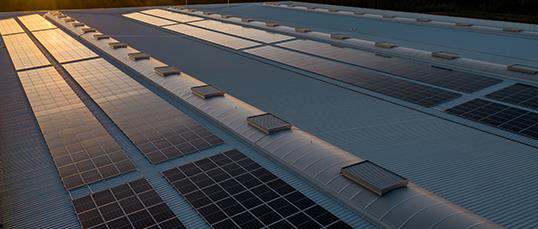

Cleaning Solar Panels

Cleaning of Buildings

Case Study – Cleaning Wind Turbines in a Wind Farm in Northwest China

Prolonged exposure to wind and sand causes paint peeling, rusting and oil staining on the wind tower, reducing its appearance, structural strength and durability, with the risk of collapse.

❌ Safety risks: Working at high altitude is dangerous, with risk of falls and injuries.

❌ Difficulty and inefficiency: Manually climbing towers or using baskets is a strenuous, intensive and slow process.

❌ Problems with thorough cleaning: Traditional automated solutions struggle to reach narrow and complex areas, such as turbine blades.

With the implementation ofAP30-P2, the operations team was able to significantly improve efficiency and safety in cleaning wind turbines. In an area with more than 120 turbines, 20 units were identified for deployment. The system was transported by truck along with water tanks and cleaning agents, successfully completing the automated aerial cleaning operations. In addition to ensuring optimal results, the system enabled maintenance data to be recorded and reports to be generated for future interventions.

✓ Cleaning Without Risks to Personnel:

The operation is done entirely remotely, eliminating the need for operators to work at great heights and drastically reducing the risk of falls and injury.

✓ Increased Safety and Stability:

The system is capable of operating up to 200 meters in height with a spraying distance of 6 meters.

The integration of real-time distance sensors ensures accurate and safe operation even in complex environmental conditions.

✓ Increased Operational Efficiency:

With traditional methods, cleaning a turbine requires 5 operators for 5 days. With AP30-P2, only 1 operator is needed to complete the task in a single day, drastically reducing time and cost.

✓ Fast and Effective Cleaning: The system supports different types of cleaning liquids, ensuring deep cleaning with immediate results.

✓ Full Coverage and Optimal Precision: Theadjustable multi-angle nozzle allows you to reach the entire surface of the turbine, including difficult areas such as the blades, ensuring even and effective cleaning.

Technical Characteristics

| Items | Specs |

|---|---|

| Weight | 13 kg |

| Power | 900 W |

| Spray Module Length | 2.5 m |

| Max. Spraying Distance | 6 m |

| Pump Pressure | 1~4 Mpa |

| Max. Flow Rate | 5 L/min |

| Capacity | 30L |

| Protection Rating | IP55 |

| Nozzle Rotation Range (Horizontal) | -45° ~ 45° |

| Nozzle Rotation Range (Vertical) | -60° ~ 35° |

| Control Method | Integrated Flight Control |

| Quick-change Nozzles | Supported |

| Liquid Level Indicator | Supported |

| Distance Detection | Supported |

There are no reviews yet.